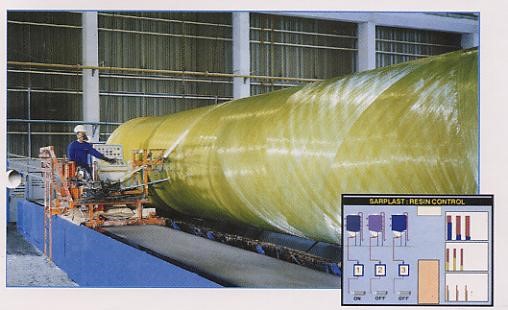

Installation of Underground GRP pipe

Installation of Aboveground GRP pipe

Repair of GRP Pipe

Tanks and Spool

Lining

Grating

Third Party inspection of long term GRP pipe tests.

Pipes will be installed as per the guidelines provided in the international standard AWWA M45 which is summarized below.

Trench Excavation

Excavation of trenches will be carried out to ensure that sides will be stable under all working conditions and dewatering will be carried out. The depth of the trench will be as required depending upon the stiffness class of the pipe

Bedding

Bedding shall be prepared by the compaction of native soil, wherever required bedding shall be prepared by compaction of crushed and graded rocks.

Laying

Pipes will be handled as per the requirement laid down by the manufacturer. Pipes will be placed in the trench conforming to the required elevation, slopes and alignment. Bell holes will be provided at the mechanical joints. In cases where the pipe needs to be laid in a curvature angular joint deflection will be maintained within the specified limit.

Joining

Pipes will be joint by various methods like Coupling Joint, Lamination Joint, and Mechanical joint and lock joint. Coupling joint will be carried out as per the manufactures recommendation so as not to exceed specified angular deflection.

Lamination joint will be carried out using the hand layup method as well as the wrap around method as required. Joint will be designed to ensure it meets the required pressure and stiffness class. In cases where not specified the joint resin shall be same as the pipe resin.

Types of Joints

- Lamination Joint

- Rubber Seal Lock Joint (RSLJ)

- Rubber Seal Joint (RSJ)

- Adhesive Joint (TB/TS and CB/CS)

- Coupling Joint

Backfilling and compaction.

Embedment material will be placed so as not to disturb or damage the pipe. Hunching will b e carried out prior to backfilling. Backfilling and compaction will be done in layers maintaining the circularity of the pipe.